Solving a locking problem in the railway sector

Case study introduction

The rail sector, with its reduced carbon footprint, stands out as a sustainable transport option that is rapidly gaining market share.

To support this growth, it is essential to have high-quality components, designed to withstand technical constraints. The LINKSY Group, with its 4 entities, plays a central role in supplying rail subcontractors with fastening solutions and electronic components.

This video presents a customer case in which Soprima met a complex technical challenge.

Customer's technical issues

This case study illustrates the technical challenges faced by subcontractors in the rail industry.

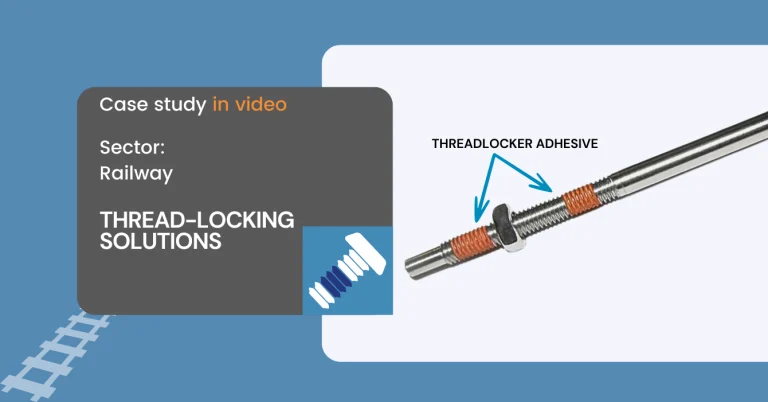

Jean-Michel Vallette, technical sales engineer, recounts the case of an initial complex order: an axle to be pre-coated in two distinct zones, separated by a nut. The main challenge was to preserve the two pre-coated zones after the nut had been screwed onto the axle.

Thanks to Soprima’s support and technical expertise, a solution was found to keep the nut in place on the axle and in the middle of the two pre-coated zones. This type of challenge highlights Soprima’s expertise in developing specific technical solutions adapted to demanding environments.

Soprima's pre-coating offer

Soprima offers a range of products adapted to strict safety and durability standards:

Dry thread brake range: Soprifix, Precote

Range of sealing products: Precote, Threebond

These high-quality products meet the stringent requirements of the rail industry and integrate perfectly into modern infrastructures and equipment.

Conclusion

Soprima has successfully solved this problem, opening up new possibilities for solving other locking challenges.

This ability to adapt makes Soprima a strategic partner for subcontractors in this sector.