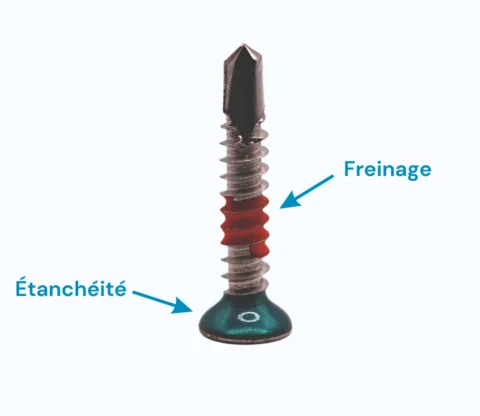

Pre-coating: an effective treatment for replacing liquid threadlockers and ensuring the sealing of assemblies

Pre-coating is a treatment method applied to the threaded or smooth part of a cylindrical component. It involves the application of a special product designed to be activated when the part is assembled, whether by screwing or press-fitting.

Our products for dry threadlocking

and sealing products

A range of products can be used : from micro-encapsulated glue to replace liquid threadlockers, to sealing resin, polyamide products for repositionable locking and anti-seize products.

Thread-locking and sealing function on all types of threaded or smooth parts

Our expertise, unique in France, is based on the constant evolution of our techniques to meet the needs of specific and complex applications. We are often involved right from the design or R&D phase, to ensure customized solutions for our customers. Our wide range of products and application processes enables us to cover a wide variety of applications:

- Fine or standard threads, from S0.7 to M30 and up to 2″ tapered.

- Parts in raw or coated steel, stainless steel, aluminum, brass, plastic, titanium, precious metals.

- Numerous finishes: galvanized, polished, palladium, etc.

- High-temperature resistance up to 200°C peak.

- Resistant to oils, fuels and other fluids.

- Low friction coefficients and, for certain products, compliance with automotive standards.

- Approved by French and foreign automakers.

Reinforcing and improving the durability of assemblies

Guaranteeing the reliability and longevity of assemblies

Significant reduction in assembly costs

Elimination of health and safety problems

The many applications of pre-coating :

Thread locking

Polyamide locking

Bonded locking

High-temperature thread locking

Thread sealing

Temporary positioning

Vibration resistance

Anti-corrosion

Anti-seizing

Friction control…